Mike Kojima posted on January 02, 2009 06:01

The designers of the VQ37VHR also strove to reduce power robbing, fuel burning friction by micropolishing the camshafts and crank. Friction is reduced further by using dry film lubricant coatings on the pistons. The pistons use an asymmetrical skirt profile with the non-thrust side of the piston skirt having its area reduced for less frictional drag. The pistons also use hard anodizing in the ring grooves to help improve ring seal over the life of the engine. The top ring of the piston is located high to reduce crevice volume and hydrocarbon emissions. Unfortunatly this makes the piston weaker for forced induction applications. With a high top ring and 11:1 compression it will be interesting to see how the VQ37VHR holds up to boost on pump gas with stock pistons.

The cam followers use slippery hydrogen less DLC (diamond like coating) coating to keep friction low. Removing the hydrogen from the carbon makes for a polar molecule that has a great attraction to oil, meaning oil wants to stick to it for better lubrication. This is a big advantage over conventional DLC that tends to repell oil. Hydrogenless DLC is a Nissan exclusive. A small pitch silent type cam drive chain also helps reduce noise and friction.

The VQ37VHR cylinder heads have straight direct angled intake and exhaust ports, indicative of a good flowing design and 4 valves per cylinder with a shallow included angle pentroof combustion chamber with two quench pads located on either side of the combustion chamber. The shallow included angle gives a low surface area to volume ratio for good thermal efficiency, while the quench pads squeeze fuel air mixture towards the centrally located spark plug as the piston rises toward top dead center to provide a more homogeneous turbulent mixture for a more efficient burn that is less likely to detonate even with the VQ37VHR's high 11:1 compression ratio.

|

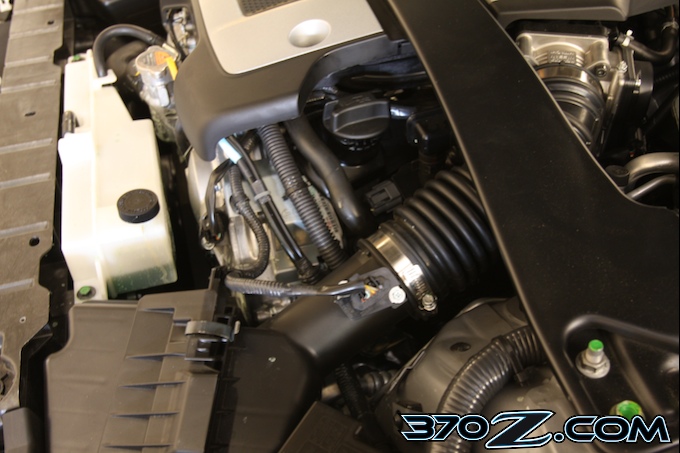

| The 370Z's free flowing air intake with dual inlets, airflow meters and throttle bodies is probably going to give aftermarket makers of cold air intake systems fits. The aftermarket had a hard time finding more power with the VQ35HR's dual inlet system and we figure it will be more of the same here. |

The incoming air is fed to the engine through twin air flow meters to dual drive by wire throttle bodies. The air is fed to a plastic intake manifold, with one large centrally located plenum chamber, much like that found on the VQ35HR. The plastic manifold material helps performance by having a very smooth interior for improved air flow and low thermal conductivity to help keep the intake air cool. The intake system looks to be very efficient, it is doubtable that the engine will respond much at all to cold air intake mods, as tuners have found with the VQ35HR. Fuel is injected via top feed injectors using a conventional sequential multi-port injection scheme. The fuel system is returnless with electronic control of the fuel pump to vary the pressure and volume of the fuel delivered to the injector rails. Exhaust gasses are routed to tubular dual wall headers to close coupled catalytic converters.

The mixture is fired by Nissans direct fire ignition system called NDIS. NDIS is a very high powered ignition system where the ECU fires individual coils mounted directly on the spark plug with no power wasting distributor or primary wires to waste spark energy. The NDIS system both reduces maintenance and improves performance by greatly reducing the likelihood of misfire.

|

| One area were the aftermarket might be able to make a big power difference in the 370Z is in the exhaust system. The piping in the Y-Pipe after the twin catalytic converters is pretty small in diameter for a 3.7 liter motor making serious power. |

|

| Underneath these heatshields the pipe is only around 1.5” in diameter where it could probably be 2.5”. |

Past the catalytic converters the exhaust merges into a single exhaust feeding to a larger transversely mounted muffler with twin outlets. As a note to tuners when we examined the car closely on a lift, we noted that the exhaust from the catalytic converters rearward is exceedingly small in diameter for an engine of this displacement and power output. It is almost as if Nissan wanted to artificially limit the power output of the engine for some reason by choking off the exhaust. We feel that a larger diameter, less restrictive exhaust may free up quite a few horsepower from the 370Z's motor.